Tizona II CNC Turning Machine

Award Winning CNC Turning Machines

Awarded 'Best CNC Turning Machinces' by the FIE Foundation at the IMTEX 2013, BIEC, Bangalore.

- Key Features

- Specification

- CNC Controller

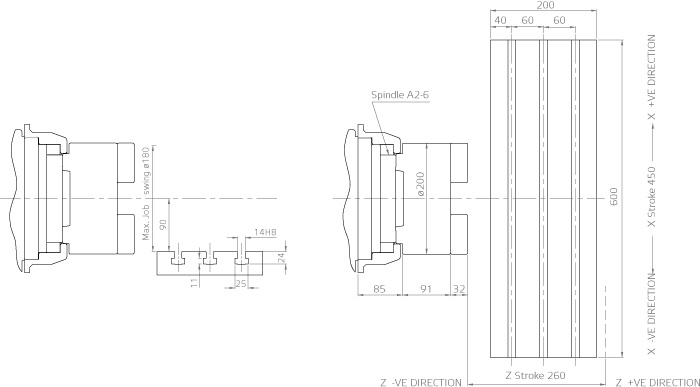

- Diagrams

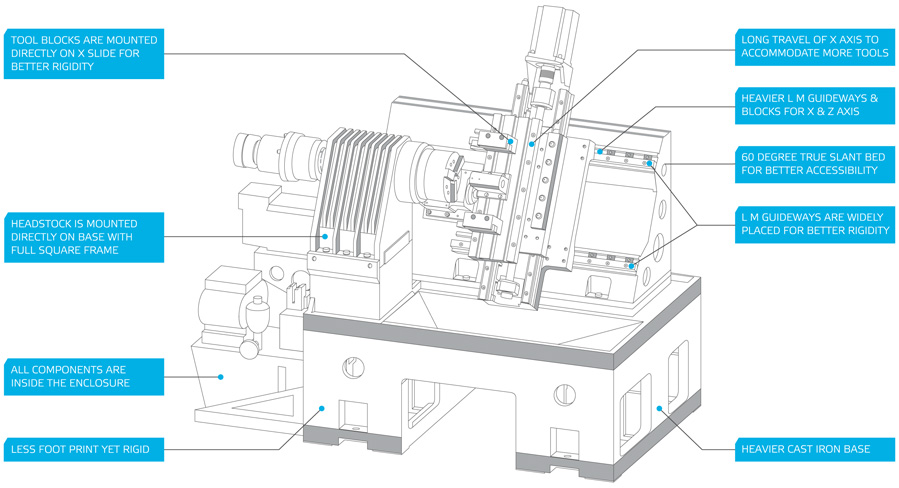

Key Features

Advantages

TIZONA CNC Chuckers are most suitable for various kind of Chucking Jobs like Bearing Races, Endshields, Flanges, Hydraulic Spares, Clutch Plates, Discs, Brakes, Brake Drums, Impellers, Tappets, etc.

Why CNC Chuckers? |

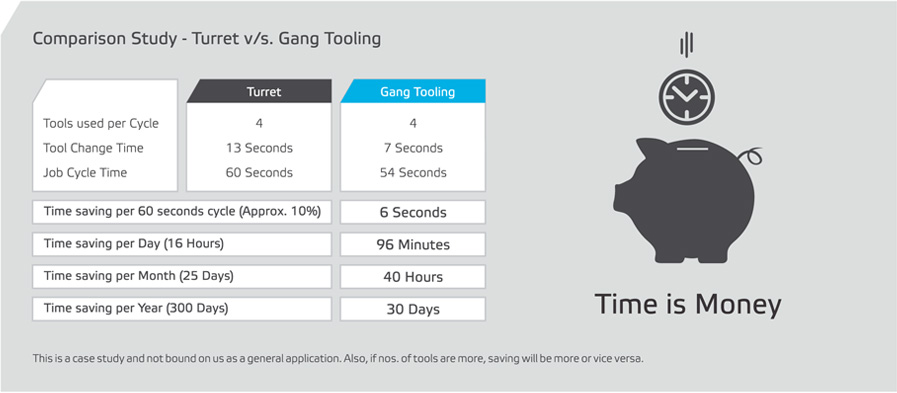

Why Gang Tooling? |

Advantages of CNC Gang Tooling Chuckers |

||

| During our application study, we found that approx. 70-80% job applications are performed through chucking only. | We have learned that approx. 60-70% job applications utilizes maximum of 4 Tools. |

|

Specification |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Smart Choice – Rexroth (Germany)

CNC Controller

The standard system supplied with Tizona Series CNC Turning Machine is Rexroth IndraMotion MTX Micro from Germany with latest technology and facilities.

|

Standard Features

|

|

Rexroth IndraMotion MTX Micro Advantages

|

||

Interface Diagrams

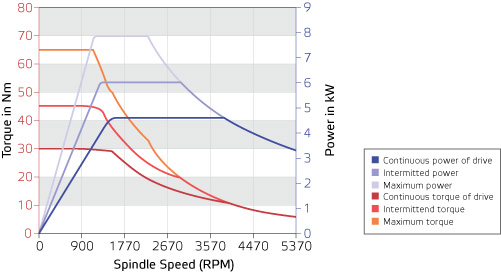

Spindle Power Torque Diagram

Options

- Chip Conveyor (For Tizona I – Side only, For Tizona II – Rear only)

- Bar Feeder

- Bar Puller

- Part Catcher

- Hydraulic Collet Chuck

- Hydraulic Hollow Chuck and Cylinder

- Auto Door

- Auto Loader

- Tooling Solution